Description

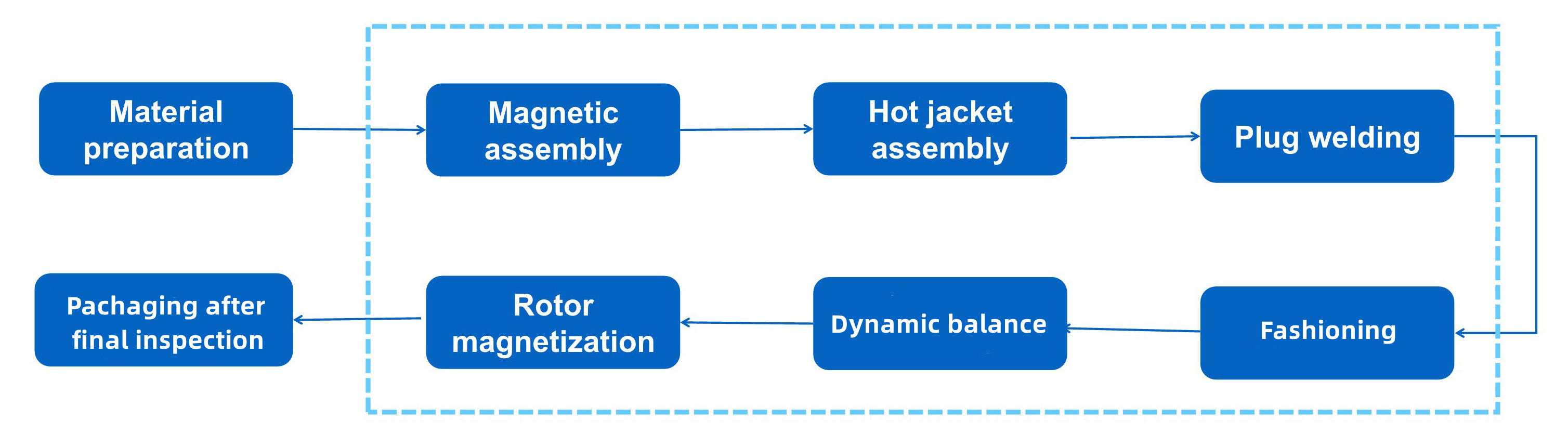

High speed motor rotor general production process

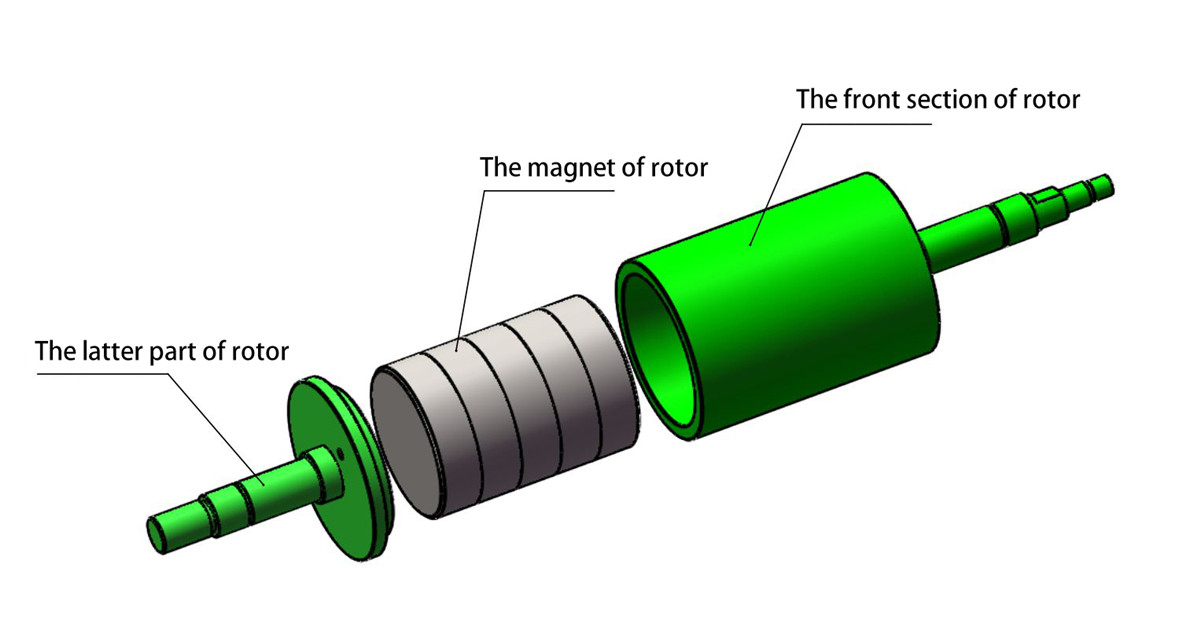

The rotor is usually composed of an iron core (or rotor core), windings (coils), shafts (rotor shafts), bearing supports, and other accessory parts.The performance of the rotor directly affects the operating efficiency, stability and service life of the whole mechanical equipment. Therefore, the rotor performance requirements are very high.Generally speaking, the rotor needs to have good mechanical strength, electrical performance, thermal stability and dynamic balance performance. At the same time, in order to meet the needs of different equipment, the rotor also needs to have different performance indicators such as speed, torque and power.

Hangzhou Magnet Power Technology has accumulated extensive experience in magnetic motor components, including magnetic rotor components, magnetic coupling components and magnetic stator components. We provide motor preassembly parts for bonding permanent magnets and metal materials according to customer requirements. We have modern production lines and advanced processing equipment, including CNC lathes, internal grinder, surface grinder, milling machine and so on.

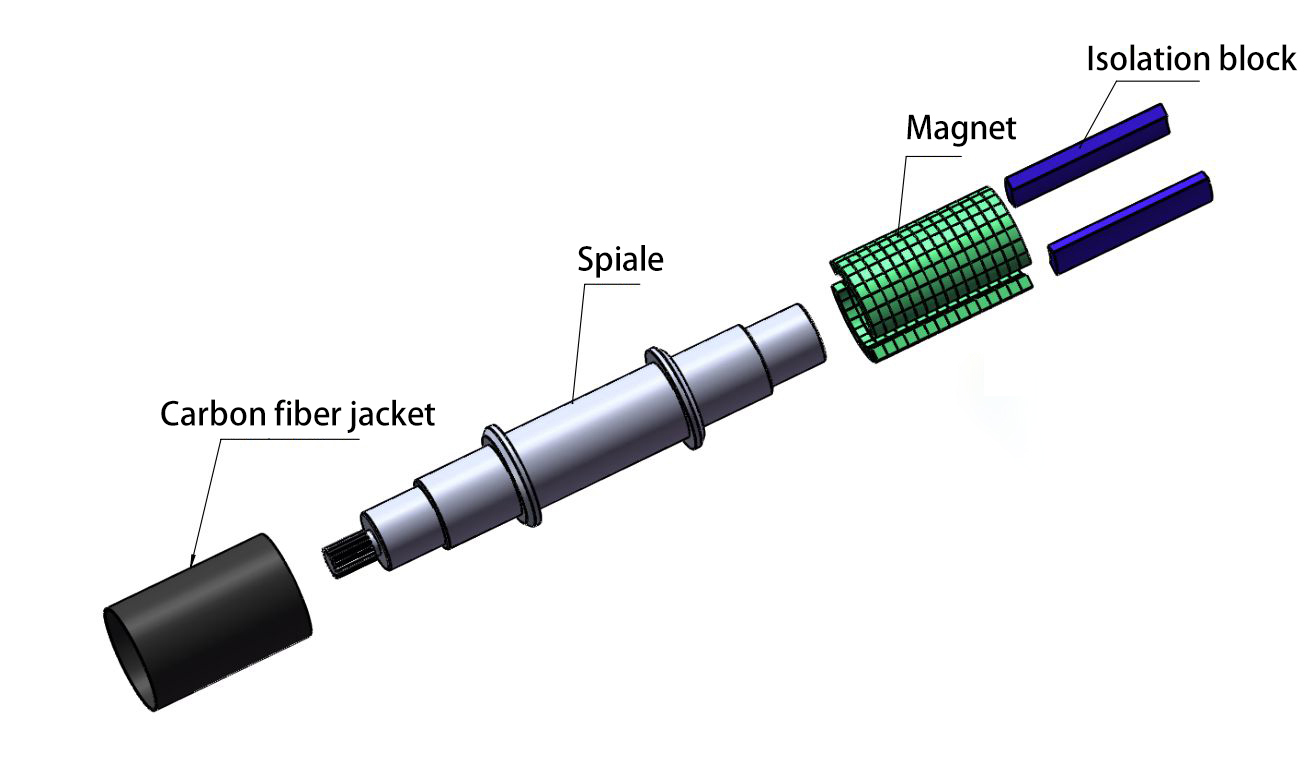

Magnetic Assembly

Our company can produce high grade such as 45EH,54UH high-speed motor rotor, weight up to 70 kg, 45EH rotor temperature 180 degrees Celsius -200 degrees Celsius, demagnetization 1.6%, speed up to 22,000 RPM. Hangzhou Magnet Power Technology Co., Ltd. It can not only provide customers with rare earth permanent magnet steel for high-speed motors, but also has the design and development, manufacturing and assembly capabilities of the entire rotor. Applied to magnetic suspension high speed motor and air suspension high speed motor. Rotor jacket materials available for production include GH4169, titanium alloy, carbon fiber.

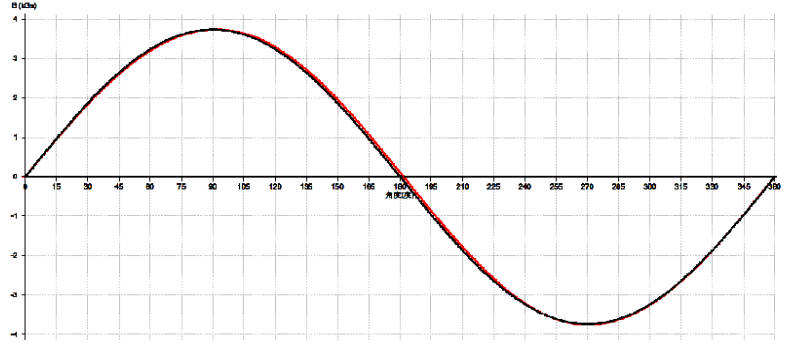

Rotor magnetizing field

| CIM-3110RMT Table Magnetic Distribution Test Report |

ItemParameter | Peak value(KGS) | Angle(degree) | Area(KG degree) | Area(degree) | Half height(degree) | ||||||||

| N | S | N | S | N | S | N | S | N | S | |||||

| Production number | Magnet Power | Magnetic poles | 2 poles | Average value | 3.731 | 3.752 | 91.88 | 88.09 | 431.6 | 423.8 | 181.7 | 178.3 | 121.2 | 118.2 |

| Batch number | The total area | 855.4KG (degree) |

Maximum value | 3.731 | 3.752 | 91.88 | 88.09 | 431.6 | 423.8 | 181.7 | 178.3 | 121.2 | 118.2 | |

| Least value | 3.731 | 3.752 | 91.88 | 88.09 | 431.6 | 423.8 | 181.7 | 178.3 | 121.2 | 118.2 | ||||

| Test date | 2022/11/18 | Judgement result | Standard deviation | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | |

| Tester | TYT | Remarks | Electrode deviation | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | |

| Cumulative error | 0.0000 | 0.0000 | ||||||||||||

|

||||||||||||||

Hangzhou Magnet Power Technology Co., LTD. produces all kinds of high speed motor rotors that are widely used in automobile motors, electric tool motors, household appliances motors, brushless motors, etc., providing professional support services for well-known motor manufacturers at home and abroad.

Hangzhou Magnet Power Technology Co., LTD. looks forward to establishing a business relationship with you. Should any of these items be of interest to you, please let us know. Looking forward to getting your inquiries.